Welcome to Workplace One

With 25 years of experience, Workplace One helps you improve your business through operations and quality management. Learn more about us. ISO Implementation

ISO Implementation

Implementing an ISO management system? We have completed more than 600 systems throughout North America covering a wide range of certifications. Put our expertise to work for you. Learn More Internal Audits

Internal Audits

Improve the effectiveness of your internal audit program. Go beyond simply meeting certification requirements and let Workplace One provide meaningful improvement to your audit management process. Learn More

Total Cycle Time

Improve cost, quality, and the time is takes to complete every process in your organization. We can show you how. Learn More

ISO Broker ServiceFind the right Registrar for your organization that fits your budget and provides amazing value. We can provide a complete review of your ISO system requirements and find the right Registrar for you. Learn More

Lean Improvement Process

A lean improvement process (also known as lean manufacturing, lean production or simply “lean”) is a systematic method for the elimination of waste within a... Learn More

Failure Mode and Effects Analysis

Failure Modes and Effects Analysis (FMEA) is a qualitative and systematic tool for evaluating a process or product to identify potential problems (failure modes) and... Learn More

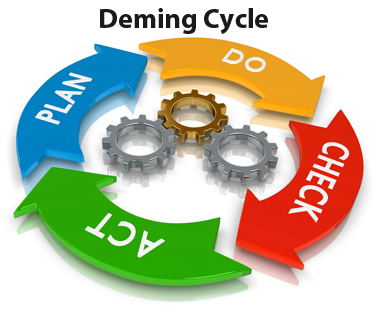

The Deming Cycle

The Deming Cycle is a systematic series of steps for gaining valuable learning and knowledge for the continual improvement of a product or process. This... Learn More

The Balanced Scorecard

The Balanced Scorecard is a management system that enables organizations to translate their strategies into specific goals and actions and track the consequent results. This... Learn More

5S Methodology

The 5S is a methodology developed to maintain an organized, clean and safe workplace in which organizations can carry out processes with a high level... Learn More

Cost of Quality

Today, most companies take into account the quality of their products and services because they recognize it as a key factor in meeting their customer’s... Learn More

Value Stream Mapping

Value Stream Mapping (VSM) is a tool that helps organizations map the flow of materials and information required to produce a product or service and... Learn More

The Kanban System

Kanban is a scheduling system for lean and just-in-time (JIT) production. It is an information system where the supply or production of a product is... Learn More

Pull Manufacturing

Pull manufacturing refers to a production system based on actual customer demand, where information flows “backwards” from market to management compared to that in traditional... Learn More

Seven Forms of Waste

The Seven Forms of Waste refers to any activity within a process that does not add value to a product or service from the perspective... Learn More

Single Minute Exchange of Die (SMED)

SMED is an acronym for Single Minute Exchange of Die, a manufacturing process that favors rapid changeovers or setups between running different machines and producing... Learn More

Takt Time

Takt Time is an expression derived from the German word Taktzeit, which can be roughly translated as “keeping a beat”, “rhythmic time” or “pace compass”.... Learn More

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is a systematic proactive approach of maintaining focus on keeping parts and machines in top-working conditions, ready to do what they’re... Learn More

Benchmarking

Benchmarking is the process where an organization gathers data of its processes and performance metrics and then compares them against those from other organizations in... Learn More

Cellular Manufacturing

Cellular manufacturing is a production system that arranges workstations and equipment in a sequence that supports a continuous flow of materials and components through the... Learn More

Continuous Flow Manufacturing

Continuous Flow Manufacturing (CFM) is a methodology that aims at the optimization of a process using minimum inventory. This is achieved by manufacturing a product,... Learn More

Flexible Manufacturing

Flexible Manufacturing (FM) is a very adaptable manufacturing process developed to react rapidly as demand patterns for different products change over time. In flexible manufacturing,... Learn More

Quality Function Deployment

Quality Function Deployment or QFD is a method that transforms qualitative customer’s demands into quantitative parameters that can be incorporated into the design of a... Learn More

Lean Manufacturing

Lean manufacturing is the systematic elimination of waste in a process. Also known as lean production or simply “lean”, this approach consists of different practices... Learn More